Some people often complain to me why it is so difficult to buy qualified solar cables. Why are there so many solar cables on the market,why is the price is different?

Solar cable is Photo-voltaic cable. Its conductor part is copper conductor or tinned copper conductor, the insulation layer is irradiation cross-linked polyolefin insulation, and the sheath is irradiation cross-linked polyolefin insulation. A large number of DC cables in solar power stations need to be laid outdoors, and the environmental conditions are bad. the cable materials should be determined according to anti-ultraviolet, ozone, drastic temperature change and chemical erosion, tide, sun protection, cold resistance, heat resistance, ultraviolet resistance, and chemical substances such as acid and alkali in some special environments. At present, there are only two standards for solar cables, one is the European Union standard, and the other is the American standard. At present, most of us use the European Union standard, because this standard is used all over the world.

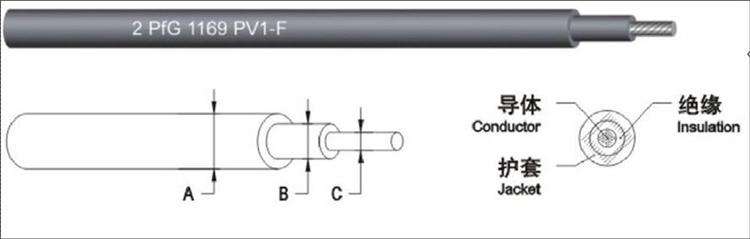

2. Conductor:

The Solar cable conductor is made of tin-plated copper, which meets the IEC standard and is a Class 5 flexible conductor. However, some manufacturers will use copper conductors as the main material, which is not meet UL or TUV standard. Although the use of copper conductors can save costs, but cable can be used less than 5 years. The copper conductors will be oxidized over a long time, and it will also cause safety risks. Some people may ask, they are all tinned copper conductors, why is the price is also cheap? This is because the square number of conductors has not been reached. Let's give an example to illustrate that solar cable 4mm and solar cable 6mm are the most commonly sold models in solar industry, and some manufacturers produce solar cable 4mm with an actual square of only 3.5 squares. Solar cable 6mm is only 5.5 square. As an enterprise specializing in the production of cables. The Electric bridges are the only standard for testing resistance products. We make sure that our raw materials are qualified in production, and when the cables are finished, we have to test every meter such as conductor, insulation, and sheath. Ensure that every meter is a qualified product.

3. Insulation:

The insulation of solar cable is the material of irradiation cross-linked polyolefin, which is also the first insulation of photovoltaic cable. However, the material used by some manufacturers to attract customers with low prices. They use PVC materials instead of XLPO. Because the solar cable is exposed outdoors all the year round, and the requirement of current is very high. If you choose PVC as a material. The coefficient of danger is very high, and if it is serious, it will be life-threatening. Therefore, I advise you not to buy some unqualified products for the sake of cheaply.

4. Jacket.

The sheath of solar cable is the material of irradiation cross-linked polyolefin, which is the second and final sheath layer of solar cable. The sheath plays a protective role, so the requirements and performance of the material must be the best. It has a good effect on heat resistance, UV protection, low temperature resistance and moisture resistance.

5. Packaging.

The solar cables produced by our company are usually 100m per roll, and we can also produce 200m, 500m or 1000 according to customer requirements. If it is more than 500 meters, we suggest that the packing is wooden wheel, which is not only convenient for transportation, but also beautiful.

a.Dual wall insulation.Electron beam cross-linked

b.Excellent resistance to U.V, oil, greases, oxygen, and ozone

c.Excellent resistance to abrasion

d.Halogen-free, flame retardant, low toxicity

e.Excellent flexibility and stripping performance

f.High Voltage and Current carrying capacity

g.TUV approved

H. Can be used 25 Years

When we buy Solar cable, we should take a closer look at the inside and outside of the product. Check the qualification of the manufacturer, whether there is certification and so on. Check the conductor to see if it is tinned and see if the sheath of the wire is the name, specification, model and meter of the manufacturer. It's best to take a lighter to light a test. If it doesn't burn, it means there's nothing wrong with the quality of the product. The selection of qualified solar cables can ensure the accident rate of the project, improve the reliability of power supply, and durability.