Power cable for industrial

Source your Power Cable requirements from ZW, leading manufacturer of Electrical Power Cable items.

Use of Power Cable

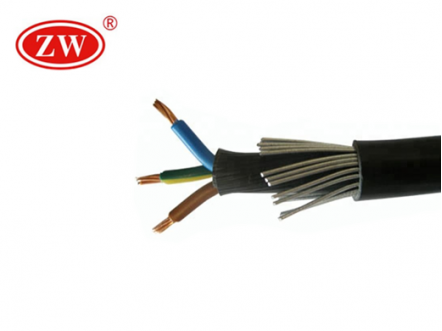

Power Cable is used to transmit and distribute power in power transmission and distribution system of 35kV or lower. Electrical power cable is generally applied to the fields including power, construction, mines, metallurgy, petrochemical industry and communication in complete replace of oil immersed paper insulated power cable and in partial replace of pvc power cable. ZW is a leading electrical cable manufacturer since 1993. We can produce many type of electrical cable such as high voltage power cable and low voltage cable.

Difference between cable and wire.

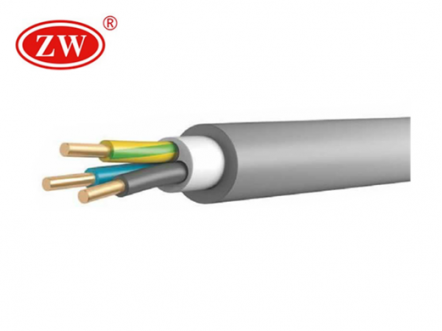

The basic main difference between a wire and a cable is that a wire is a single conductor, while a cable is a set of conductors. However, some wires are coated with a very thin layer of PVC. In the case of cables, they run parallel and are twisted or bonded together to form a single case.

Common Power cable faults

Electric cable surface markings - According to national standards, the surface of the wire should have the manufacturer's name, product model number and rated voltage continuous markings. This is conducive to the use of the wire in the process of problems can be found in a timely manner when the manufacturer, consumers must pay attention to this point when buying wire. At the same time, consumers should pay attention to whether the manufacturer's name, product model and rated voltage marked on the certificate of conformity are consistent with the printed logo on the surface of the wire to prevent counterfeit products.

Wire appearance--Consumers should pay attention to the appearance of the wire should be smooth and even, insulation and sheathing layer without damage, the logo printing is clear, no greasy feeling when hand-molded wire. From the cross-section of the wire, the thickness of the insulation or sheath on the entire circumference of the wire should be uniform, should not be off-core, insulation or sheath should have a certain thickness.

Conductor diameter - consumers should pay attention to the purchase of wire conductor diameter and certification on the cross-section of the express line, if the conductor cross-section is small, easy to make the wire heat caused by short circuit. It is recommended to use 1.5 square millimeters and above for household lighting lines; 2.5 square millimeters and above for air conditioners, microwave ovens and other high-powered household appliances.

Normative use - should be standardized wiring, fixed line is best to use BV wire through the pipe, pay attention to the wiring do not touch bad wires, in the room decoration do not touch bad wires; in a line in the middle of the joints; wire access to electrical boxes (boxes) do not touch the line; in addition to large power consumption of household appliances such as air conditioning should be a separate power supply all the way line; weak electricity, strong electricity with the wire is best to keep a certain distance.

Cable line common faults are mechanical damage, insulation damage, insulation moisture, insulation deterioration, over-voltage, cable overheating fault. When the above faults occur in the line, should cut off the power of the cable fault, looking for the fault, the fault inspection and analysis, and then repair and testing, the cut in addition to the cut, to be eliminated after the fault, before restoring power supply.